As is well known, high-purity alumina ceramics contain a higher amount of alumina than general alumina ceramics. Therefore, high-purity alumina ceramics have a wide range of applications due to their excellent properties such as high mechanical strength, high hardness, high temperature resistance, and corrosion resistance. Do you know how to prepare high-purity alumina ceramic products? Below, the editor will introduce to you:

Method for preparing high-purity alumina ceramic products:

1. Preparation of high-purity alumina powder

The preparation of high-purity alumina ceramics has a high requirement for the original powder, usually based on purity; 99.99% crystalline phase α The main raw material is aluminum oxide powder. The characteristics of high-purity ultrafine alumina powder determine the performance of the final preparation of high-purity alumina ceramics. In the preparation process of high-purity alumina powder, it is required to have high purity, small particle size and uniform distribution, high powder activity, and low degree of agglomeration. This allows for the production of high-purity alumina ceramics at relatively low temperatures. Therefore, in order to prepare high-purity alumina ceramics, it is necessary to first prepare high-purity alumina powder. At present, the main preparation methods for high-purity ultrafine alumina powder include improved Bayer method, aluminum hydroxide thermal decomposition method, precipitation method, and active high-purity aluminum hydrolysis method

2. Preparation methods of high-purity alumina ceramics

After obtaining high-purity alumina powder, it is prepared into well formed billets, and suitable sintering methods are selected according to product requirements and costs to prepare high-purity alumina ceramics. At present, commonly used sintering methods include: atmospheric pressure sintering, hot press sintering, two-step sintering, discharge plasma sintering, microwave sintering, etc

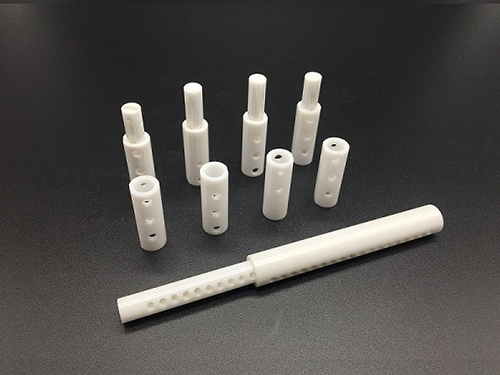

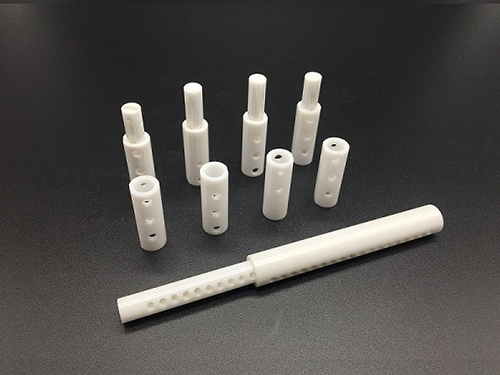

In summary, it is the preparation method of high-purity alumina ceramics. High purity alumina ceramic parts have high melting point, high hardness, and high mechanical strength, which can be widely used in industries such as precision bearings, instruments, instruments, pen making, mechanical accessories, punching and extrusion holes, oil fields, hydrochloric acid laboratories, hardness measuring instruments, fishing gear, counterweights, decoration, precision processing, and so on

Dongguan Zhongli Nano Ceramics Technology Co., Ltd. © Copyright 2023

【Backstage】