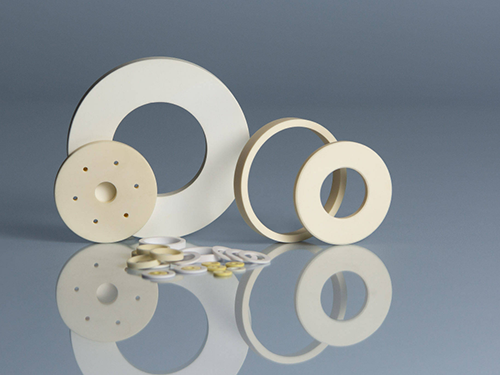

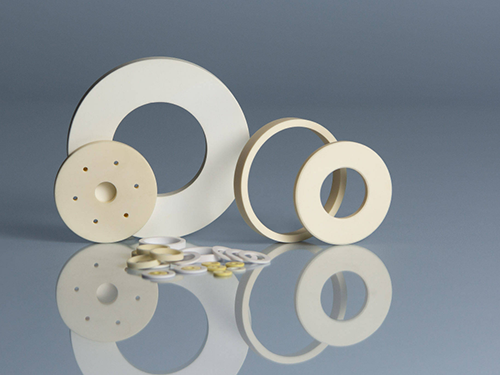

Alumina ceramics, due to their excellent conductivity, mechanical strength, and high-temperature resistance, can be widely used in fields such as electronics, electrical, mechanical, textile, aerospace, etc. However, due to the high sintering temperature, which requires a large amount of energy consumption and high requirements for thermal equipment, the use range of alumina ceramics is also limited to a certain extent. In order to effectively reduce the sintering temperature of alumina ceramics, we can use special sintering processes to lower the sintering temperature. Can we reduce the sintering temperature of alumina ceramics by using hot pressing sintering technology? Below, the editor will introduce to you:

Adopting the hot pressing sintering process, the green body is heated while being pressurized. Sintering is not only achieved through diffusion mass transfer, but also plays an important role in plastic flow. The sintering temperature of the green body will be much lower than that of normal pressure sintering. Therefore, hot pressing sintering is one of the important technologies to reduce the sintering temperature of alumina ceramics. As for alumina ceramics, ordinary sintering under normal pressure must be fired to above 1800 ℃, while hot pressing sintering only needs to be fired to around 1500 ℃

However, in production practice, in order to achieve good comprehensive economic benefits, the above low combustion technologies are often used in combination with each other. Compared with other methods, the method of adding auxiliary combustion additives has the characteristics of low cost, good effect, and simple and practical process. In addition, from a material perspective, various mechanical and electrical properties of alumina ceramics have been greatly improved through doping modification technology. Replacing high alumina content ceramic bodies with low alumina content ceramic bodies is also an effective technical means commonly used by enterprises to reduce the sintering temperature of alumina ceramic products

In summary, we can see that the use of hot pressing sintering technology can indeed reduce the sintering temperature of alumina ceramics to a certain extent. Of course, in addition to using special sintering processes such as hot pressing sintering technology to reduce the sintering temperature of alumina ceramics, we can also reduce the sintering temperature of alumina ceramics by optimizing the formula system, improving the fineness and activity of raw materials, and adding sintering additives

Dongguan Zhongli Nano Ceramics Technology Co., Ltd. © Copyright 2023

【Backstage】