|

|

Hexagonal: This form of boron nitride has the most applications because of its high lubrication properties, electrical conductivity, and thermal stability.

Cube: Cubic boron nitride has the same high resistivity and thermal conductivity as diamond. It does not dissolve in steel parts, so it is a good abrasive material.

Amorphous: The amorphous state of boron nitride is comparable to amorphous carbon in terms of structure and properties.

Atomically thin: Despite its ultra-thin properties, this BN polycrystalline form is characterized by high thermal conductivity, increased surface adsorption, and good dielectric properties.

Nanotube: As one of the recent developments, nanotube technology has been promoted with the use of boron nitride. This rolled up form of hexagonal BN is structurally similar to carbon nanotubes. However, BN nanotubes have higher electrical insulation as well as better resistance to heat and chemical reactivity.

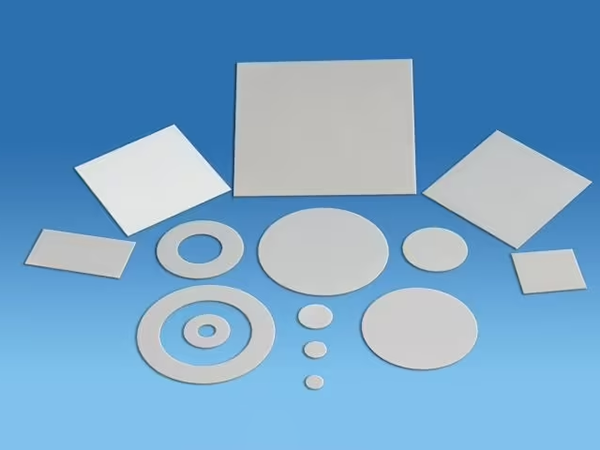

Excellent machinability: (can be easily machined into any geometry)

Lubricity: boron nitride increases the coefficient of friction of lubricating oil while reducing the possibility of wear.

High resistivity: (excluding aerosols, paints and ZSBN)

Low density: (density range 2.1 to 3.5 g/cm 3)

High thermal conductivity: (with excellent thermal conductivity, very low thermal cycling behavior in use)

Anisotropy: (the thermal conductivity of different planes is different with respect to the direction of compression)

Corrosion resistance: good chemical inertness; (Boron nitride insoluble in common acids)

High temperature resistance: (Melting point of boron nitride is 2,973°C)

Non-wetting: (ceramic crucible used as molten glass and metal)

High dielectric breakdown strength: (> 40 KV/mm)

Low dielectric constant: (k=4)

Use of boron nitride ceramics

Socket plate for high temperature furnace

Molten glass and metal crucible

Electrical insulators for high temperature and high pressure

Plasma chamber linings and fittings

Nozzles for non-ferrous metals and alloys

Thermocouple protective tube and sheath

Laser stand

1.3Y,5Y,8Ymol yttrium stabilized zirconia zirconia powder

2.Open mold processing: dry pressing, CIM injection molding, isostatic pressing.

3.Appearance processing: surface grinding, outer diameter/inner diameter grinding, fine engraving machining, grinding, polishing grinding.

● Socket plates for high temperature furnaces ● Molten glass and metal crucible ● Electrical insulators for high temperature and high pressure ● Plasma chamber linings and fittings ● Nozzles for non-ferrous metals and alloys ● Thermocouple protection tubes and sheathing ● Laser supports ● Plasma arc welding equipment, diffusion source wafers and semiconductor crystal growth equipment and processing equipment ● High power electronics applications as heat sinks

By product

Application requirement

Design and research

Optimization scheme

Strict essence

Precision drawing

piggyback

Select ingredients

Multiple forming

Fired blank

Grinding and polishing

Precision machining

Multiple gage

Professional survey

Qualified product

Package and ship

Dongguan Zhongli Nano Ceramics Technology Co., Ltd. © Copyright 2023

【Backstage】