|

|

● High wear resistance ● High corrosion resistance ● High oxidation resistance ● High thermal conductivity, good thermal conductivity ● Strength remains unchanged in high temperature environments ● Thermal shock resistance ● Fast forming, high yield, pollution-free ● Low density, light weight ● Long service life

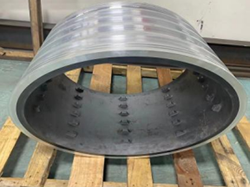

The outer diameter of the silicon carbide wear-resistant barrel body can reach up to 1000mm. The silicon carbide wear-resistant barrel body can provide rough damage after sintering, with a diameter tolerance of ± 0.5mm. The outer diameter and end face of the silicon carbide wear-resistant barrel body can be matched for precision machining of the sealing surface. The silicon carbide wear-resistant barrel body is subjected to strict size and surface fluorescence penetration testing at the factory. The density of silicon carbide wear-resistant barrel is greater than 3.14g/cm3, and the Vickers hardness is above 23GPa, indicating high wear resistance. The wear-resistant silicon carbide barrel material has passed TUVFDA certification and can meet the requirements for food grade medium transportation.

1. High purity silicon carbide powder

2. Open mold processing: dry pressing, CIM injection molding, isostatic pressing.

3. Appearance processing: surface grinding, outer diameter/inner diameter grinding, fine engraving machining, grinding, polishing grinding.

Nano sand mills, conveying equipment, conveying pipelines, etc

| Basic characteristic | Main ingredient purity(wt%) | 99 | |

| colour | black | ||

| density(g/cm³) | 1350 | ||

| hydroscopicity(%) | 0 | ||

| Mechanical characteristic | Modulus of elasticity GPa | 450 | |

| Compressive strength(MPa) | 224 | ||

| Bending strength(MPa) | 400 | ||

| Poisson's ratio | 0.14 | ||

| Vickers hardness(GPa) | 30 | ||

| Thermal characteristic | Hottest operating temperature(℃) | 1600 | |

| Coefficient of thermal expansion(1/℃×10-6) | RT~500℃ | 3.9 | |

| RT~800℃ | 4.3 | ||

| Thermal conductivity(W/m x K) | 40 | ||

| Thermal shock resistance△T(℃) | 300 | ||

| Electrical characteristic | Volume resistivity | 25℃ | 3x10 to the sixth power |

| Dielectric constant | 10GHz | ||

By product

Application requirement

Design and research

Optimization scheme

Strict essence

Precision drawing

piggyback

Select ingredients

Multiple forming

Fired blank

Grinding and polishing

Precision machining

Multiple gage

Professional survey

Qualified product

Package and ship

Dongguan Zhongli Nano Ceramics Technology Co., Ltd. © Copyright 2023

【Backstage】