|

|

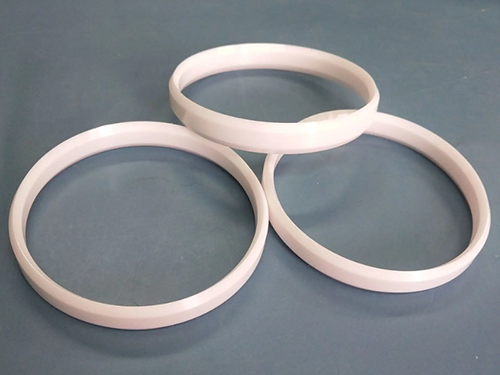

● High hardness, high toughness, high bending strength ● High wear resistance, low friction coefficient, ● strong corrosion resistance ● Low thermal expansion coefficient ● Good insulation ● Long life ● High temperature resistance

High processing precision, special ceramic formula, quality assurance, cutting edge width less than 0.1mm, diameter specifications from 30mm to 260mm complete, can be customized. Easy to clean, save ink, long-term use of the ring mouth is still bright and dense, good sealing performance, effectively prevent ink leakage.

1. 3Y, 5Y, 8Ymol yttrium stabilized zirconia zirconia powder

2. Open mold processing: dry pressing, CIM injection molding, isostatic pressing.

3. Appearance processing: surface grinding, outer diameter/inner diameter grinding, fine engraving machining, grinding, polishing grinding.

● Automotive, electronics, toys and other printing workshops, supporting the corresponding size of the oil cup printing machine

| Material | zirconia | Fracture toughness MPam1/2 | 8 | Modulus of elasticity Gpa | 200 |

| Hardness (HV) | 1350 | colour | white | Poisson'sRatio | 0.3 |

| Thermal Expansion Coefficient (10-6°c) | 10 | Water absorption(%) | <0.01 | Component content(%) | ZrO₂ ≧95 |

| Firing temperature | 1550-2600 | Compressive strength Mpa | 2000 | Dielectric constant(1MHZ) | 28 |

| Temperature resistance(°C) | 1800 | hardness Hra | 88.8 | Mirror polishing(Ra) | ≦ 0.05 |

| Specific Gravity(g/cm3) | 6.05 | Volume resistance (cm) | > 1012 | Thermal conductivity (W/m x K) | 5 |

| Flexural Strength (MPa) | 800-1000 | coarseness(um) | ≦ 0.8 | Thermal shock resistance△T℃ | 400 |

By product

Application requirement

Design and research

Optimization scheme

Strict essence

Precision drawing

piggyback

Select ingredients

Multiple forming

Fired blank

Grinding and polishing

Precision machining

Multiple gage

Professional survey

Qualified product

Package and ship

Dongguan Zhongli Nano Ceramics Technology Co., Ltd. © Copyright 2023

【Backstage】