|

|

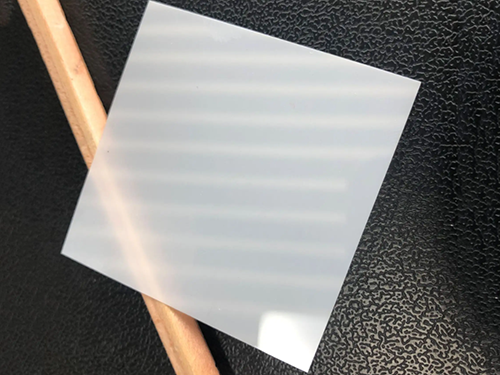

● High toughness ● High hardness ● High wear resistance ● Self-lubricating ● No residue ● Strong corrosion resistance ● Low coefficient of thermal expansion ● Good insulation ● Long life ● High temperature resistance

High purity nano zirconia powder, adding special solvent fully mixed ball milling, granulation to produce uniform and stable zirconia powder, through isostatic pressing, heating degreasing, high temperature sintering molding. Grinding and polishing through the grinding fluid, single-sided and double-sided grinding, to meet customer requirements of product zirconia ceramic plate thickness

1. 3Y, 5Y, 8Ymol yttrium stabilized zirconia zirconia powder

2. Open mold processing: dry pressing, CIM injection molding, isostatic pressing.

3. Appearance processing: surface grinding, outer diameter/inner diameter grinding, fine engraving machining, grinding, polishing grinding.

● New energy, petroleum, chemical, nuclear, aerospace, military, electric power, medical, machinery and other fields

| Material | zirconia | Fracture toughness MPam1/2 | 8 | Modulus of elasticity Gpa | 200 |

| Hardness (HV) | 1350 | colour | white | Poisson'sRatio | 0.3 |

| Thermal Expansion Coefficient (10-6°c) | 10 | Water absorption(%) | <0.01 | Component content(%) | ZrO₂ ≧95 |

| Firing temperature | 1550-2600 | Compressive strength Mpa | 2000 | Dielectric constant(1MHZ) | 28 |

| Temperature resistance(°C) | 1800 | hardness Hra | 88.8 | Mirror polishing(Ra) | ≦ 0.05 |

| Specific Gravity(g/cm3) | 6.05 | Volume resistance (cm) | > 1012 | Thermal conductivity (W/m x K) | 5 |

| Flexural Strength (MPa) | 800-1000 | coarseness(um) | ≦ 0.8 | Thermal shock resistance△T℃ | 400 |

By product

Application requirement

Design and research

Optimization scheme

Strict essence

Precision drawing

piggyback

Select ingredients

Multiple forming

Fired blank

Grinding and polishing

Precision machining

Multiple gage

Professional survey

Qualified product

Package and ship

Dongguan Zhongli Nano Ceramics Technology Co., Ltd. © Copyright 2023

【Backstage】