With the improvement of modern people's living standards, people's requirements for the quality of daily necessities are also increasing, including ordinary tableware. Zirconia cutting tools and chopsticks are deeply loved by people. Zirconia ceramics have advantages such as high toughness, high bending strength, high wear resistance, excellent insulation performance, and thermal expansion coefficient close to steel. Do you know the hardness of zirconia ceramics? Let's introduce to you:

Zirconia ceramics have high hardness. The hardness test report of 3Y zirconia used as a tool provides data greater than 9, second only to diamond. The definition of diamond hardness should be 10, and the crystal hardness should be around 7, which is not as high as zirconia hardness

The molecular weight of pure zirconia is 123.22, the theoretical density is 5.89g/cm3, and the melting point is 2715 ℃. Usually contains a small amount of hafnium oxide, which is difficult to separate, but has no significant impact on the performance of zirconia. Zirconia has three crystal forms: monoclinic, tetragonal, and cubic. Zirconia only exhibits monoclinic phase at room temperature. When heated to 1100 ℃, it transforms into a tetragonal phase, and when heated to a higher temperature, it transforms into a cubic phase

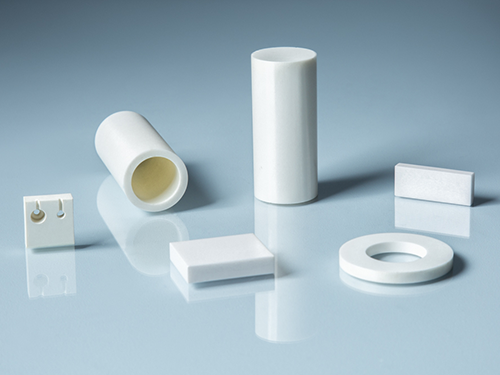

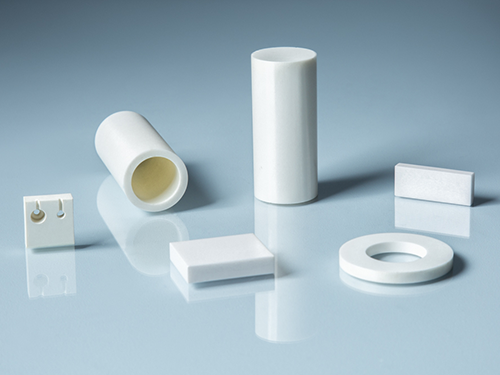

Zirconia ceramic cutting tools have the characteristics of high strength, wear resistance, non oxidation, non rusting, acid and alkali resistance, anti-static, and non reaction with food. At the same time, the blade shone like jade. It is the ideal high-tech green cutting tool in the world. At present, the main products on the market include zirconia ceramic dinner knives, scissors, razors, surgical knives, etc. At present, it has been successfully applied to heating elements and equipment in oxidizing atmospheres above 2000 ℃, and electrode materials for magnetic fluid power generation are also actively being studied

Dongguan Zhongli Nano Ceramics Technology Co., Ltd. © Copyright 2023

【Backstage】